Happy Meal Ball Maze Toy

Technologies:

SolidWorks

Injection Molding

Rapid Prototyping

Design for Manufacturability

Project Overview

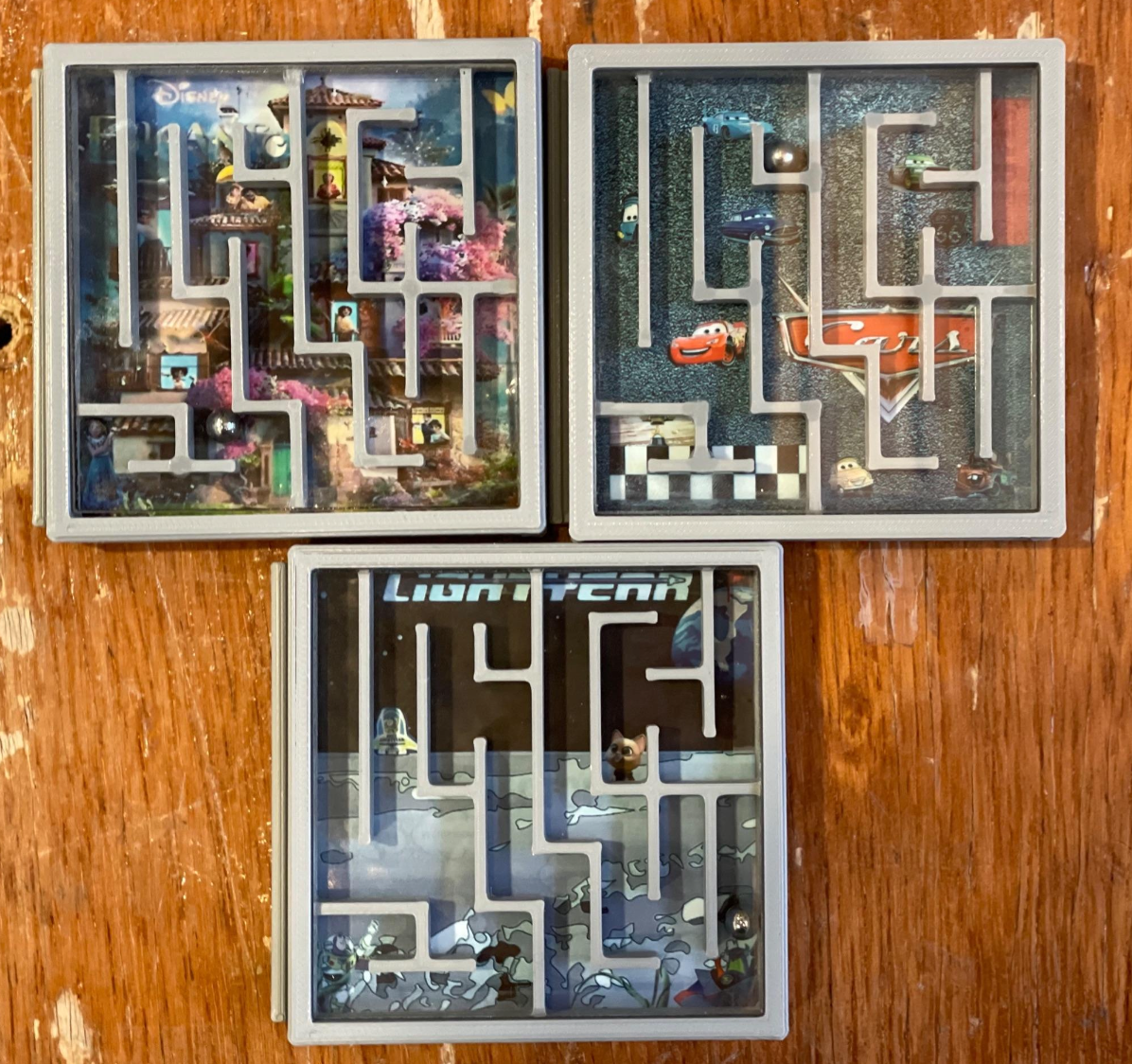

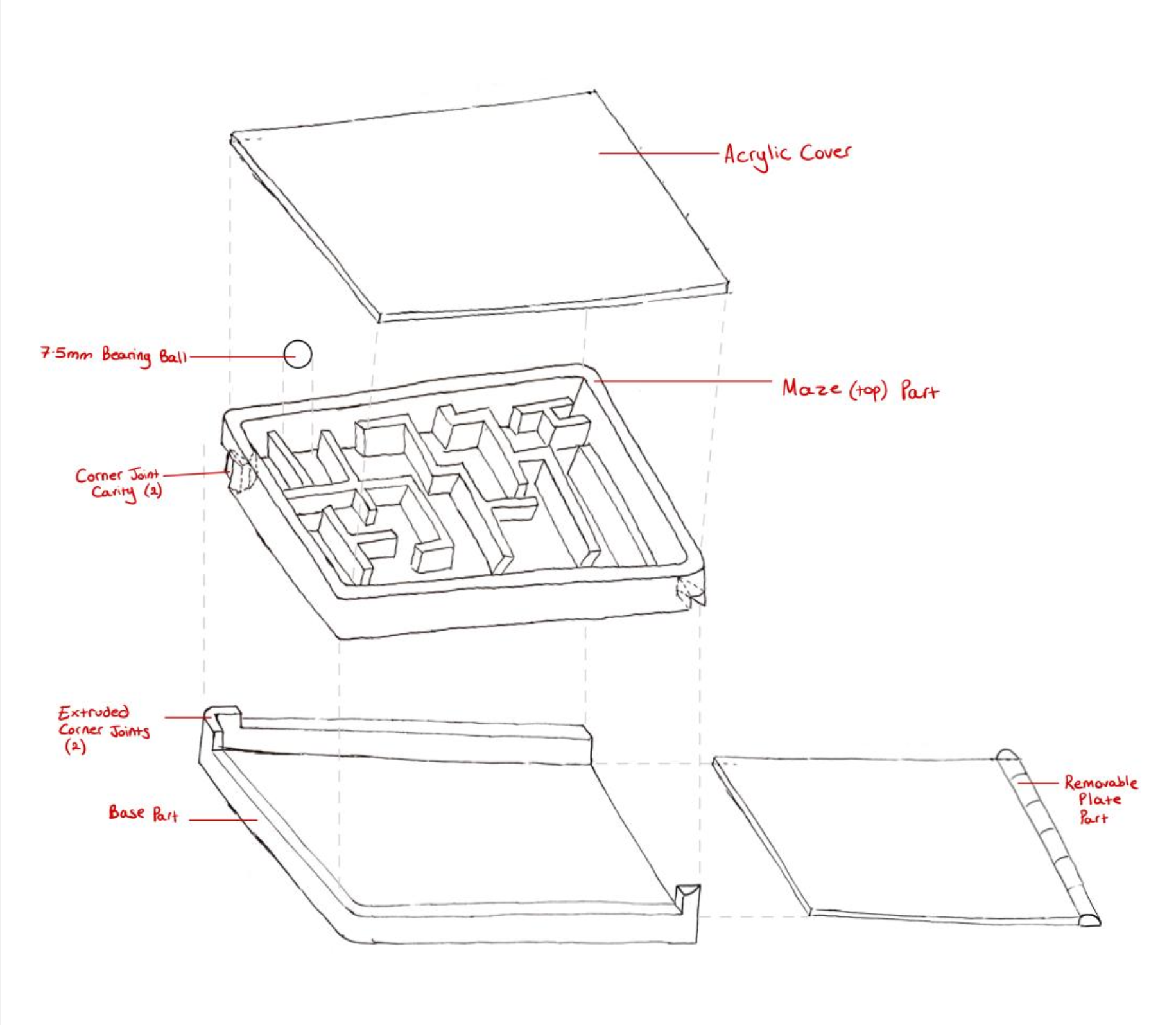

- Designed a puzzle maze toy with interchangeable backgrounds for Happy Meals.

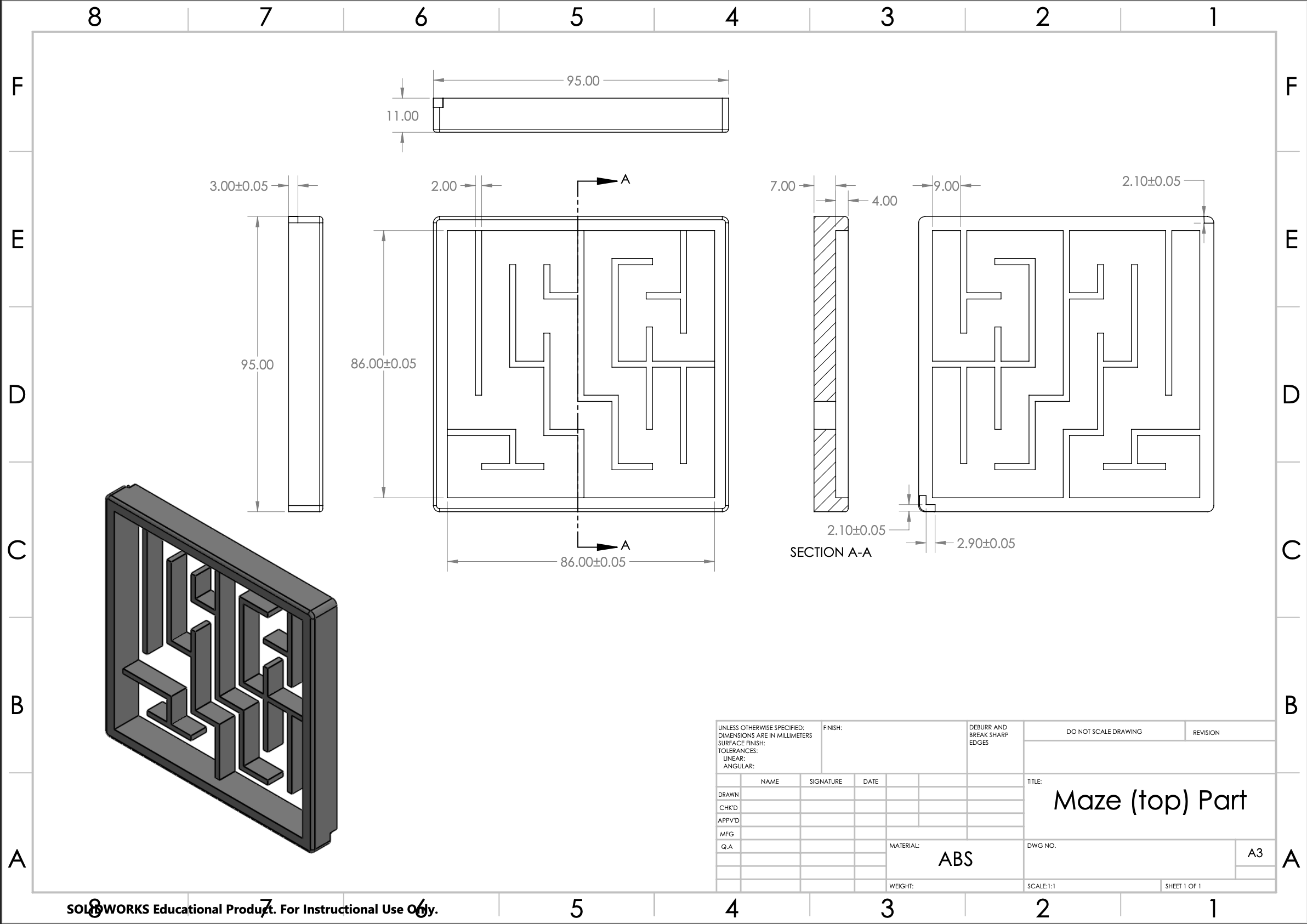

- Used SolidWorks for CAD modeling and tolerance analysis for manufacturability.

- Developed a cost‑effective design with ABS plastic to ensure durability and safety.

- Implemented injection molding manufacturing with an estimated cost of $0.38 per toy.

- Conducted user testing and improved friction‑fit tolerances for an optimal user experience.

Technical Drawings & Prototyping

Project Documentation

Cost Analysis

- Manufacturing Cost: The total cost per unit was estimated at $0.38 using injection molding.

- Material Costs: ABS plastic was selected for its durability, low cost, and recyclability.

- Production Feasibility: The mold was designed for high‑volume manufacturing, reducing per‑unit costs as production scales.

Marketing Analysis

- Target Audience: Children ages 3‑10, incorporating popular themes (Encanto, Cars, Lightyear).

- Brand Alignment: The design integrates with McDonald’s existing Happy Meal branding, enhancing collectibility.

- Sustainability Considerations: The toy is designed for recyclability and minimal material waste, aligning with sustainability goals.

Project Results & Key Findings

- User Testing: Positive feedback was received on ease of use and durability.

- Manufacturability Success: The toy was successfully manufactured using injection molding, demonstrating feasibility.

- Improvements: Adjustments to snap‑fit tolerances and friction joints improved the final design’s assembly quality.